About us

- Syed Sagheer Abbas Rizvi

- Nov 10, 2022

- 3 min read

Since 2002, we are working in the field of transmission. We have a lot of experience making high-precision gears and gearbox designs, as well as ball screws, lead screws, and linear guideways. As the company grew, WANFU set up affiliated share-holding factories in China. These factories were added to the WANFU Group and worked on linear transmission solutions, mostly making, and designing ball screws, lead screws, actuators, linear guideways, gearboxes, gear worms, and worm gears.

· Worm wheels and gears

Details about the product:

1. Screw gears made of high-quality steel and made to order

2. Carburizing, phosphating, electroplating, pickling, zinc passivation, and custom were all ways to treat the surface.

3. Apply to many different fields.

We do machining work based on drawings or samples from customers.

China knows Wanfu Precision as one of the top companies that makes and sells plastic screw gear. With more than 30 years of experience and hundreds of qualified employees, Wanfu Precision is one of the best at what it does. Our factory makes high-precision products and can make plastic screw gears to your specifications.

· spur gears

The teeth on spur gears are curved. In other words, they are involute gears with tooth shapes that are part of the involute curve. In general, the involute shape is the most common type of gear tooth. This is because it can handle small errors in the Centre distance, it is easy to make production tools for it, it has thick roots that make it strong, and so on.

· Bevel Gear

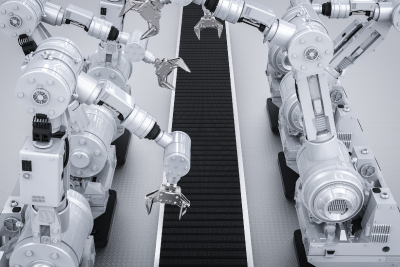

Gears, which are also called cogwheels, are mechanical devices made of wheels with teeth that send mechanical energy from one part to another. They are often used in machines that are used in multiple industries, like drive systems and production lines. They are also used in industries as different as aeronautics, mining, textiles, and pharmaceuticals. The purpose of the gears determines their shape (bevel gears, spur gears, helical gears, etc.) and the materials they are made of.

1. High-quality stainless steel in the shape of a T.

2. It is easy to put together and use.

3. Very well made and easy to use.

4. Some of the benefits are high speed and mechanical efficiency, low noise, heavy load, long life, a mechanism that uses little power, and low starting torque.

5. Time to make: 2 to 3 weeks

· Ball screw

This ball screw has been used in many kinds of electric pruning tools. People are using electric tools to prune trees, grapes, and other plants more and more.

And a lot of plants for the garden. With a capacity of 10,000 sets per month, WY Precision Company Limited can supply a lot of key components for ball screws.

· Pulley reducer for the SDC series

1.Fully synthetic, high-performance lubricants are mixed in.

2.Advanced processing technology is used to make the twin-pitch worm. This is so that the clearance can be changed.

3.A better way to change the clearance

4.Two tapered roller bearings are put on one end of the screw to get rid of the error caused by the screw's thermal elongation and make sure the meshing is accurate.

5.The shell is made of a rigid and light high-strength aluminum alloy that is cast by gravity.

6.The worm gear is made of a special copper alloy that is resistant to wear. It doesn't wear down easily, and the locking side gap stays the same for a long time.

· The RV Series Reducer

Description

1.Contains high-performance, fully synthetic lubricants.

2.Advanced processing technology is used to make the twin-pitch worm. This is so that the clearance can be changed.

3.A better way to change the clearance

4.Two tapered roller bearings are put on one end of the screw to get rid of the error caused by the screw's thermal elongation and make sure the meshing is accurate.

5.The shell is made of a rigid and light high-strength aluminum alloy that is cast by gravity.

6.The worm gear is made of a special copper alloy that is resistant to wear. It doesn't wear down easily, and the locking side gap stays the same for a long time.

Worm gears are just tapered roller bearings that are bigger.

Comments