Applications and Uses of worm gear

- Syed Sagheer Abbas Rizvi

- Dec 9, 2022

- 3 min read

Worm gear is a type of mechanical power transmission that is commonly used in small engines. It uses the rotational motion of a worm to turn the teeth on a gear, which in turn transfer power from one place to another. Worm gears are highly efficient and provide smooth operation with minimal noise or vibration.

This type of gear system has some distinct advantages over other types; it can transmit large amounts of torque while occupying minimal space. This makes worm gears ideal for use in small engines where space is at a premium, such as outboard motors and other motorized equipment that require compact designs. Additionally, they are simple to install and maintain, making them very user-friendly.

Worm gears are also known for their durability; they have the ability to last many years without needing replacement or repair if they are properly maintained.

Lifts and elevators

Lifts and elevators are a crucial part of modern life, allowing us to easily move between floors in buildings. Whether you need to travel up or down, these contraptions have come a long way since the first lift was installed in 1743. One of the key components used in lifts is the worm gear, which plays an important role in ensuring smooth and safe operation.

The worm gear has been around for centuries and is basically two gears meshing together – one shaped like a screw (the ‘worm’) and the other like a ring (the ‘gear’). The combination of these two elements means that the gear only moves when it is rotated by its counterpart – meaning that once the lift stops at its destination, it won’t move until powered again.

Rolling mills

Rolling mills are a type of machine used to shape metal into various forms. They are most often used in applications such as wire and sheet rolling, especially in the construction industry. The rollers themselves are generally constructed with a worm gear drive mechanism, which helps ensure precision and accuracy during operation.

A worm gear drive system is composed of two parts, the worm wheel and the worm shaft. The wheel has teeth that mesh with those on the shaft when it rotates, creating a unique rotational speed ratio between them. This allows for greater control over the rolling process than other types of drives, making it ideal for specialty uses such as

thin strips or intricate shapes from sheet metal. Additionally, because this type of drive requires little maintenance and is less prone to wear and tear than other types, it can be used reliably over long periods of time without requiring replacement or repair.

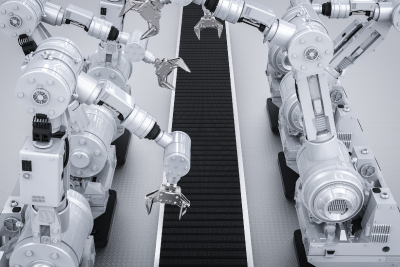

Conveying engineering

Conveying engineering is an important part of the industrial world, and it is not something to be taken lightly. Worm gears are one type of conveyor system used to transmit power between two or more rotating shafts, while also reducing rotational speed, increasing torque, and allowing for directional changes. Specifically designed with a cylindrical gear in the shape of a screw thread, worm gears are most commonly used in cases where there is limited space available. They can also provide greater positional accuracy than traditional helical gears due to their design which allows for a large amount of contact between teeth at all times.

Worm gears are known for their high degree of mechanical efficiency, meaning that they help conserve energy by transferring power from one shaft to another with minimal losses.

Summary

In conclusion,worm gears are an incredibly useful tool for making precise and accurate movements in machinery. They enable a wide range of motion, have high torque capabilities, and require very little maintenance. Their unique design makes them ideal for applications where space is limited or the traditional use of other gearing systems would be too costly. Worm gears can even be used to reduce the speed or increase the torque of a rotating shaft or transmission.

Comments