Gearbox Components - Complete Measurement

- Lo Jm

- Mar 1, 2024

- 3 min read

One approach to diminish quality costs is to incorporate all estimations in one single machine that's reasonable and vigorous sufficient for utilize in generation. This diminishes machine speculation, han- dling endeavors, and set-up time. Being able to degree in generation too makes a difference to diminish sit out of gear times by decreasing trans- harbor ways to climate-controlled measuring offices.

In any case, the moo adaptability of gages could be a enormous disadvantage. Gauges are regularly precisely planned for one characteristic as it were. Plan changes to this highlight require a unused gage, coming about in tall costs and lead times. On the other side, high-precision measuring machines are utilized. CMMs regularly require the clean and air-conditioned environment of a measuring room. Measuring machines are characterized by the next degree of adaptability — compared to gages — whereas being worked by prepared staff.

Ways to performed Roughness measurement: o -Cylindrical Gears - Spur and Helical o -Bevel Gears o -Rotational symmetric components such as e.g. shafts o -Bearing seats including axial bearings

Roughness measurement result are given o -as a number of measuring print out. o -full roughness profile with all parameters Parameters Ra, Rz, Rt, Rmax, R3z,Rq, Rpc,Rk,Rpk, Rvk, Mr1,Mr2, R,AR

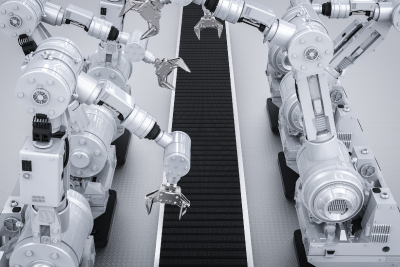

Figure 1 Surface Roughness Measurement On Precision Measuring Center.

Integrating Surface Roughness Measurement into the CMM

The roughness measurement is typically carried out on special measuring devices with linear feed. In this case the component and the roughness sensor are manually positioned relative to one another for every measurement. So, a lot of manual adjustment and set-up process for each component is required. Since the positioning is done manually, the position at which the roughness measurement is performed cannot be absolutely identical, and thus the reproducibility of the measurement result is impaired.

Integrating the roughness measurement on a coordinate measuring machine offers several advantages. The highly accurate axes of the coordinate measuring machine are available for positioning the probe. The measurement can there- fore always be carried out at exactly the same position. In addition, the roughness measurement can be integrated into the measuring sequence. In conjunction with an automatic probe changer, set-up and set-up times are completely eliminated. Figure 1 shows the roughness measurement on the tooth flank of a cylindrical gear (upper photo) and on the axial bear ing seat of a crankshaft (lower photo).

A skidded system for roughness measurement is used. Thus, the reference plane for the measurement result is the surface of the component and not the feed axis of the machine. This is an important difference from standard surface roughness measurement systems using a straight axis as the reference plane. With a straight reference, the involute curve of a gear flank is part of the measurement. This has two main disadvantages; one is that the involute is part of the measurement and has to be filtered, including the risk of also filtering information about the surface. The second disadvantage is that the probe cannot be kept perpendicular to the surface as the standards call for, which can, depending on the curvature, also influence the measurement result. Using the four axes of the measuring machine, a generating movement can be realized by always keeping the probe perpendicular to the surface. The downside of a multi-axes movement is that the control quality of the axes can influence the measurement result. This can be avoided by using a skidded system where the skid forms the reference.

Comments