Remember these considerations while purchasing gears

- Syed Sagheer Abbas Rizvi

- Nov 4, 2022

- 4 min read

Purchasing equipment might be challenging if you don't have a basic understanding of the many sorts of gadgets available on the market and how they differ from one another. Many different types of gears fall into different categories depending on their design, functionality, or the material from which they are manufactured.

We've provided you with this article's recommendations and instructions for choosing the best gears tominimize uncertainties as much as possible during your gear acquisition process:

What is Gear Manufacturing?

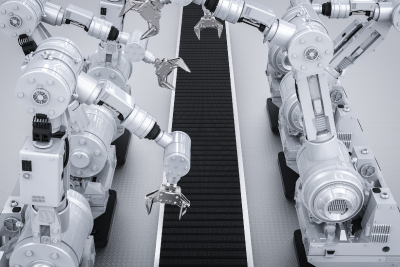

Whether the materials are cast, extruded, cut, or forged, the process of making the gears is what we refer to as gear manufacturing. Forming and machining are the two categories into which this manufacturing process can be separated.

· Direct casting, sketching, modeling, or extrusion of various tooth forms into molten or powdered casting materials are all examples of shaping.

· Both grinding and finishing procedures are included in machining.

High degrees of accuracy and monitoring is necessary during the gear manufacturing process since any errors in the shape, finish, or size could have disastrous consequences. Depending on the material and kind of gear, as well as the required quality, the procedure calls for several processing steps to be performed in order.

Types of Gears

Although there are various sorts of gears, we may distinguish between them using the classification criteria we used: their material, form, or function.

Based on their material

Even though steel is the most typical material for most gears, particularly across a variety of industrial sectors, many other materials can be used to make devices, including bronze, tin, aluminum, cast iron, ductile iron, and even metal powders. Plastic gears are also present.

Steel offers an outstanding balance of durability, resistance, and weight, which is one of the main reasons it is a material that is used extensively. In addition to being wear-resistant, this material's cost is reasonable, and its physical and mechanical characteristics can be enhanced through heat treatment.

Based on their shape

The axes' positions—parallel, intersecting, or non-intersecting—determine the geometry of the gear. We may then discuss spur, bevel, helical, rack & pinion, and other gear types from there.

Spur Gears

Spur gears are often utilized for a variety of applications since they provide great precision and don't require time-consuming or expensive production methods.

They are built on cylindrical wheels with a cylindrical pitch surface that is straight-toothed, and parallel to the shaft.

They don't take into account axial loads (thrust load).

Bevel Gears

In this instance, the two axes come together at a specific place and the gears form a bevel shape.

The bevel is carved along both the pitch surface and the gear teeth.

Spiral bevel gears, angular gears, crown gears, miter gears, hypoid gears, and zerol bevel gears are examples of bevel gears.

Helical Gears

They are frequently utilized in applications that call for speed since they can move heavier loads noisily than spur gears while producing higher loads.

Thrust bearings are required because the usage of helical gears generates a thrust force in the axial direction.

Rack Gears

The teeth of a rack gear are cut at the same distance along a straight bar or flat surface, and they have the same size, shape, and length.

The linear rotational motion is produced by meshing with a cylindrical pinion gear since the radius of a rack's pitch cylinder is limitless.

Straight tooth racks and helical racks are two different types of racks, but they both have rows of straight teeth.

Based on their function

In industrial machinery, the car industry, tools, as well as in products like appliances, toys, and other items, and gears are used relatively frequently.

Depending on their function, gears can be divided into several categories:

Spur Gears

Spur gears are frequently employed to raise or decrease an object's power, including gasoline pumps, blenders, clothes dryers, washing machines, and dryers.

Speed adjustment is one of its other applications. They can be found in kitchen mixers and wristwatches when utilized for this purpose.

Bevel Gears

Straight: utilized in lathes, milling, and turning equipment, bottling machinery, and vending machines.

Spiral: In bicycles, motorcycles, and other compact vehicles, as well as in industrial engineering and naval architecture, spiral-shaped devices operate at fast speeds.

Hypoid: The automotive industry, as well as harvesting equipment or mill and excavator actuators, including wheeled excavators.

Helical Gears

Helical gears are frequently used in machinery when the actuators must operate at faster speeds (hospitality machines) or with less noise (automotive, HVAC).

They are frequently used in machines that need parallel shafts for high-torque transmission.

Rack Gears

Rack gears are frequently incorporated into simple linear actuators, which convert the rotation of a wheel that is driven manually or by a motor into a linear motion.

Power steering is one of its most common uses, along with train tracks on steeply sloping terrain, sliding doors, and pneumatic actuators.

Where to buy gears

Investing in the proper equipment is crucial to preventing accidents that could prove to be quite expensive.

The vibration produced by the meshing, which also produces noise, is one of the factors that directly affect the service life of gears.

To the complete satisfaction of our customers, Wanfu Group provides the most comprehensive technical assistance and prototype design services if you are considering purchasing gear and need advice.

Conclusion:

Wanfu Group has specialized in discovering the best

solutions for companies. Wanfu Group is a top manufacturer of gear motors and speed reducers.

Due to all of these factors, Wanfu Group is the perfect business partner for manufacturing, distribution, and customer service, from your initial concept to the finished product. Contact us today to successfully launch the creation of your new project.

Comments