The Silent Workhorses: Why Gears Remain Essential in Robotic Joints

- Lo Jm

- Dec 31, 2025

- 3 min read

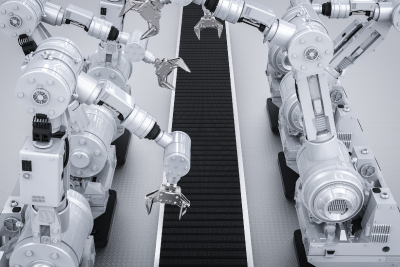

When we imagine advanced robotics, we often picture smooth, silent machines moving with almost magical precision. What we don’t see are the tiny, intricate worlds of metal teeth meshing together inside every joint. Despite the rise of direct-drive motors and magnetic actuators, gears are far from obsolete. In fact, they are the fundamental enablers of robotic strength, precision, and practicality.

The Core Challenge: Power vs. Precision

A robotic joint has a difficult job. The motor that generates movement is typically small and fast-spinning, but the robot arm itself needs to move slower, with immense force and pinpoint accuracy. This is where gears perform their first miracle: transmission and torque multiplication.

A simple gear system can convert a motor’s high speed, low-torque rotation into the low speed, high-torque output required to lift a payload or make a precise movement. Without gears, motors would need to be impractically large and powerful to generate the same force directly.

Types of Gears Powering Modern Robotics

Not all gears are created equal. The choice depends on the joint’s mission:

Planetary Gears: The champions of compact power. Their concentric design allows them to handle very high torque loads in a small, stable package, making them ideal for the core joints of industrial arms and humanoid robots.

Harmonic Drives (Strain Wave Gearing): The kings of precision. Known for near-zero backlash (the slight "play" between gear teeth), exceptional compactness, and high reduction ratios. They are indispensable in surgical robots, satellite positioning systems, and any application where microscopic accuracy is non-negotiable.

Cycloidal Drives: The robust powerhouses. Using eccentric cams and disc pins, they offer extremely high shock load resistance, longevity, and high reduction ratios. They are often found in heavy-duty industrial robots that work in demanding environments.

Spur & Helical Gears: The workhorses for parallel shafts. Helical gears, with their angled teeth, offer smoother and quieter operation than straight-cut spur gears, making them suitable for applications where noise and vibration must be minimized.

The Critical Metrics: What Makes a Great Robotic Gear?

When engineers select a gear for a robot joint, they’re not just picking a shape. They are optimizing for a delicate balance of key properties:

Backlash: The enemy of precision. This is the slight gap between meshing teeth that causes a small "dead zone" when reversing direction. Modern precision gears aim to eliminate this entirely.

Efficiency: How much of the motor’s power is lost as heat and friction. Higher efficiency means less energy waste and longer battery life for mobile robots.

Stiffness/Torsional Rigidity: The gear’s resistance to twisting under load. High stiffness ensures that the robot’s end-effector moves exactly as commanded, without unwanted flexing.

Torque Density: The amount of torque a system can deliver relative to its size and weight. Robotics demands maximum power in a minimal space.

Beyond Movement: The Role of Gearboxes

Gears are rarely used alone. They are integrated into a gearbox or reducer—a sealed system that includes the gear train, bearings, and lubrication. The gearbox is a critical subsystem that protects the gears, manages heat, and ensures long-term, maintenance-free operation. The choice between a standard off-the-shelf gearbox and a custom-designed one can define a robot's performance and cost.

The Future: Integration and Intelligence

The evolution of gears in robotics isn't stopping. The trend is toward highly integrated mechatronic units. In these modules, the motor, gearbox, feedback sensor (like an encoder), and even the drive electronics are combined into a single, compact "smart joint." This simplifies design, improves reliability, and allows for more sophisticated control.

Furthermore, materials science is pushing boundaries. Advanced composites, specialized polymers, and novel lubrication techniques are making gears lighter, stronger, and more efficient than ever before.

Conclusion: An Indispensable Partnership

While alternatives exist for specific applications, the fundamental physics of force, space, and control ensures that gears will remain at the heart of robotic actuation for the foreseeable future. They are the unsung heroes, the translators between the digital commands of a controller and the powerful, graceful physical motion of a machine. The next time you see a robot paint a car, perform surgery, or explore Mars, remember: it’s all happening on the shoulders of perfectly engineered, tirelessly spinning gears.

Comments