The Versatile World of Gears: Applications Across Industries

- Lo Jm

- May 23, 2025

- 3 min read

Updated: May 28, 2025

Introduction

Gears are among humanity’s oldest mechanical innovations, yet they remain indispensable in modern technology. These toothed wheels, designed to transmit torque and motion, have evolved to meet the demands of diverse industries. From ancient water mills to cutting-edge robotics, gears enable precision, efficiency, and power transfer. In this blog, we explore the fascinating applications of gears across various fields.

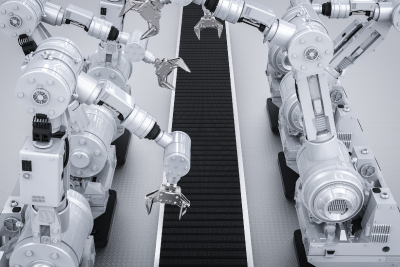

1. Industrial Machinery: The Backbone of Manufacturing

Gears are the unsung heroes of factories and production lines. In industrial settings, they power conveyor belts, assembly robots, and heavy-duty machines like lathes and presses. For example, planetary gear systems are critical in high-torque applications such as mining equipment, where durability and load-bearing capacity are paramount. Gear reducers also adjust motor speeds to optimize energy use, ensuring smooth operations in manufacturing plants worldwide.

2. Automotive Engineering: Driving Motion Forward

Your car relies on gears at every turn. Manual and automatic transmissions use intricate gear trains to regulate engine power and wheel speed. The differential gear system allows wheels to rotate at different speeds during turns, enhancing stability. Electric vehicles (EVs) employ compact, high-efficiency gears to transfer power from motors to wheels, minimizing energy loss. Even hybrid vehicles depend on gears to seamlessly switch between combustion engines and electric motors.

3. Timekeeping: Precision in Every Tick

The mechanical watch is a marvel of micro-scale gear engineering. Tiny gears, or "pinions," work with escapement mechanisms to translate the unwinding of a spring into precise time measurements. Similarly, grandfather clocks use gear trains to control pendulum motion and chime sequences. These applications demand flawless craftsmanship, as even a micron-level imperfection can disrupt accuracy.

4. Aerospace: Gearing Up for Extreme Conditions

Aircraft and spacecraft push gears to their limits. In jet engines, turbine gears withstand extreme temperatures and rotational speeds to generate thrust. Helicopters rely on complex gearboxes to transfer power from engines to rotors while managing vibration. Meanwhile, satellite deployment systems use lightweight, corrosion-resistant gears to ensure reliable operation in the vacuum of space.

5. Robotics: The Art of Controlled Movement

Modern robots owe their agility to precision gears. Collaborative robots (cobots) use harmonic drive gears for backlash-free motion in assembly tasks. Industrial robotic arms depend on helical or bevel gears to achieve multi-axis movement with pinpoint accuracy. Even humanoid robots utilize miniature gears in joints to mimic natural motion, enabling applications from healthcare to disaster response.

6. Renewable Energy: Powering a Sustainable Future

Wind turbines harness gears to convert slow rotor rotations into high-speed generator motion. The planetary gearboxes in these turbines amplify torque efficiently, making wind energy viable. Similarly, hydroelectric plants use massive gears to regulate water flow and turbine speed. Even solar tracking systems employ gears to tilt panels optimally toward the sun throughout the day.

7. Medical Devices: Life-Saving Precision

Gears play a quiet yet vital role in healthcare. MRI machines use non-magnetic gears to position patients with sub-millimeter accuracy. Surgical robots integrate sterilizable, zero-backlash gears for delicate procedures. Prosthetic limbs also rely on compact gear systems to replicate natural joint movements, improving mobility for amputees.

ConclusionGears are far more than simple mechanical components—they are enablers of innovation. As industries evolve, so do gear technologies. Advances in materials (like carbon fiber or 3D-printed alloys) and smart gear systems with embedded sensors are pushing the boundaries of efficiency and adaptability. Whether in a wristwatch or a Mars rover, gears will continue to drive progress, proving that even ancient inventions can remain revolutionary.

Comments