What is bevel gear and how does it operate?

- Syed Sagheer Abbas Rizvi

- Dec 7, 2022

- 3 min read

Devices comprised of toothed wheels, such as gears or cogwheels, are used to transmit mechanical power between two parts. In machinery utilized in several industrial processes, such as manufacturing lines and drive systems, as well as in industries as diverse as mining, aviation, pharmaceuticals, and textiles, they are frequently used.

The design of the gears (bevel gears, spur gears, helical gears, etc.), as well as their components, are determined by the application for which they are produced.

We will primarily discuss what bevel gear is and how it functions in this post to comprehend its applications and learn how to choose the most suitable one for our project.

What is bevel gear used for?

Every type of bevel gear is typically used for a certain operation:

Straight bevel gears

Straight-bevel gears are nevertheless widely used in clocks, dentist drills, hand drills, and vending machines even though they are less frequently used than other types of gears, in part because of the noise that they make while they operate.

In some industries, like the processing of materials, they are still employed. Common applications for them include flow control valves, lawn and garden equipment, drills, grinders, and compression systems for the gas and oil industries.

Spiral bevel gears

These gears' teeth have been altered. When it's essential to reverse the direction of the shafts' rotation, bevel gears are used. In comparison to a straight bevel gear, spiral bevel gears' curved teeth allow for smoother meshing and more tooth-to-tooth contact.

As a result, vibrations and noise that typically occur when gears, including straight bevel gears and others, move quickly are diminished.

Because of its construction, spiral bevel gears allow for specific mounting deflections without significantly raising the strain on either end of the teeth. They also offer a high degree of control over the way the teeth mesh.They are frequently used in motorcycle and bicycle gears because they can be used at high speeds.

Hypoid gears

In many instances, when speeds reach 1,000 revolutions per minute, hypoid gears are used. They are nonetheless suitable for low-speed applications that need a very smooth motion or a silent operation, despite this.

Hypoid gears are frequently employed in multistage gearboxes at the output stage, which calls for slower speeds and greater torques. Hypoid gearboxes are utilized in rear axles most frequently in the automotive industry, particularly in large vehicles.

Motion "below the center" is made possible by their angles, which include a right-hand spiral on the main gear and a left-hand spiral on the pinion. As a result, the driveshaft can be positioned lower on the vehicle, lowering the center of gravity and lessening the impact on the passenger area.

Real applications of bevel gears

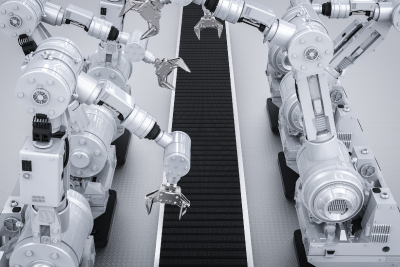

Bevel gears have a wide range of uses, from the aerospace industry to the mining industry (wheeled excavators, stacker and scoop actuators, dredges, mill actuators, conveyor belts, etc). (high-speed straight and spiral bevel gears, special steels and processes, air pre-heater, etc.).

, they are frequently used in conical mills, sand mixers, forklifts, cooling towers, ship actuators, pharmaceutical packaging equipment, polyethylene sheet manufacturing, automotive and rail transmissions, and high-speed offset printing.

Angled bevel gears are utilized in robots for confined places and in ferrous metallurgy for the vertical supports of rolling mills.

Bevel gears are crucial components in the packaging, processing, and machinery used to make cans in the food processing industry.

Conclusion:

After learning about all the functions and qualities of bevel gears, you might want to take it a step further and start implementing them into your projects.

When selecting the bevel gear types for your projects, do you need further information? Contact us, and our team of professionals can help you decide which gear is best for your plans.

Comments