Why Gear Precision is the Heartbeat of Mechanical Harmony

- Lo Jm

- Jun 12, 2025

- 3 min read

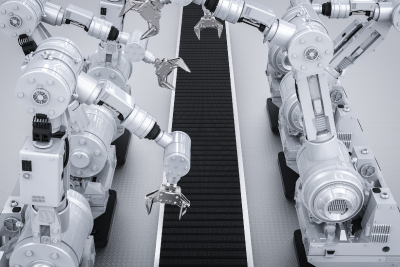

Gears. They're the unsung heroes inside everything from your wristwatch to wind turbines, transmitting motion and power with elegant efficiency. But what separates a smooth, silent, long-lasting gear system from one that whines, wears out prematurely, or even fails catastrophically? The answer lies in a concept fundamental to their performance: Gear Accuracy.

What Exactly is Gear Accuracy?

It's not just about how "good" a gear looks. Gear accuracy refers to the degree to which the actual manufactured gear deviates from its perfect theoretical design geometry. Think of it as the difference between a meticulously crafted musical instrument and a rough approximation. Every tiny variation in tooth profile, spacing, alignment, or runout introduces imperfections that ripple through the entire system.

Why Does it Matter? The High Cost of "Close Enough"

Compromising on gear precision isn't an option in demanding applications. Here's why:

Noise & Vibration (NVH): Inaccuracies cause teeth to mesh imperfectly, leading to impacts, rattles, and whines. This is critical in automotive transmissions, robotics, and precision machinery where quiet operation is essential.

Efficiency & Power Loss: Imperfect meshing creates friction and parasitic losses. More precise gears transfer power more smoothly, reducing energy waste and heat generation.

Wear & Tear: Poor contact patterns due to inaccuracies cause localized high stress and accelerated wear (pitting, scuffing). This drastically shortens gear life and increases maintenance costs.

Load Capacity: A gear system's ability to handle torque without damage is directly compromised by inaccuracies that create uneven stress distribution.

Positioning Accuracy: In applications like CNC machines or robotics, backlash (play between meshing teeth) and transmission errors caused by inaccuracies lead to positioning errors and reduced repeatability.

Reliability & Safety: Ultimately, significant inaccuracies can lead to unexpected failures, especially under high loads or in critical systems (aerospace, heavy machinery), posing safety risks.

Measuring the Imperfections: The World of Gear Metrology

Gear accuracy isn't a single number; it's a symphony of parameters defined by international standards like ISO 1328 (cylindrical gears) and AGMA 2015/2000-A88 (common in North America). These standards categorize errors into groups:

Tooth Profile Errors (e.g., Profile Deviation fᵧ, Slope Deviation fHα, fHβ): How closely the actual tooth flank matches the ideal involute (or specified) curve? Deviations affect smoothness of engagement and noise.

Tooth Spacing Errors (e.g., Single Pitch Deviation fₚ, Pitch Variation Fₚ, Cumulative Pitch Error Fₚₖ): Are the teeth spaced equally around the gear? Uneven spacing causes velocity fluctuations and noise.

Runout Errors (Radial Runout Fᵣ, Axial Runout Fₐ): Does the gear wobble as it rotates? Runout introduces eccentricity, affecting backlash consistency and meshing.

Lead Errors (e.g., Helix Angle Deviation fHβ, Total Helix Deviation Fβ): For helical gears, is the tooth line straight and correctly angled along the face width? Errors cause edge loading and uneven wear.

Backlash: The intentional clearance between meshing teeth. While necessary, controlling backlash precisely is vital for smooth operation and minimizing lost motion.

Specialized gear measuring machines (GMMs) and coordinate measuring machines (CMMs) with advanced probes and software are used to meticulously measure these deviations against the theoretical master model.

Achieving Precision: From Design to Inspection

High gear accuracy is the result of a controlled process:

Robust Design: Considering manufacturing tolerances, expected loads, thermal expansion, and deflection upfront.

Precision Manufacturing: Utilizing high-accuracy processes like grinding (for hardened steels), skiving, honing, or shaving. Modern CNC gear cutting machines are marvels of precision.

Material & Heat Treatment: Consistent material properties and controlled heat treatment (hardening, tempering) are crucial to minimize distortion and achieve dimensional stability.

Rigorous Metrology: In-process and final inspection using calibrated gear measuring equipment is non-negotiable for verifying conformance to specifications.

Proper Mounting & Assembly: Even the most accurate gear can perform poorly if mounted with misalignment or excessive runout in the housing/bearings.

The Future: Pushing the Boundaries

The demand for ever-higher precision continues, driven by:

Electrification: Quieter operation is paramount in EVs.

Miniaturization: Tiny gears in medical devices and micro-mechanics require nanometer-level tolerances.

High-Speed Applications: Aerospace and turbomachinery demand exceptional accuracy at extreme RPMs.

Advanced Materials & Processes: New alloys, additive manufacturing (3D printing), and superfinishing techniques are expanding possibilities.

AI & Machine Learning: Used in metrology data analysis for predictive maintenance and process optimization.

Conclusion: Precision is Not Optional

Gear accuracy is far more than a technical specification on a drawing; it's the fundamental determinant of performance, efficiency, longevity, and reliability in power transmission systems. Investing in understanding, specifying, manufacturing, and verifying gear precision pays dividends in smoother operation, lower noise, reduced maintenance, and enhanced safety. As mechanical systems become more sophisticated and demanding, the pursuit of ever-greater gear accuracy remains at the core of engineering excellence. The next time you hear a machine purr quietly or rely on precise movement, remember the invisible symphony of precision happening within its gears.

Comments