The Mighty Gear: How These Toothed Wheels Make Machines Move

- Lo Jm

- Jun 3, 2025

- 4 min read

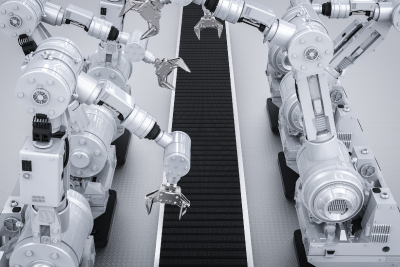

Gears are everywhere. From the intricate mechanism of a wristwatch to the powerful drivetrain of a car, from wind turbines harnessing the breeze to the robotic arms assembling electronics, these seemingly simple toothed wheels are fundamental to transmitting motion and force in our mechanical world. But how do they actually work? Let's delve into the fascinating mechanics behind gears.

The Core Principle: Teeth in Mesh

At its heart, a gear is a rotating circular machine element with cut teeth around its perimeter. The m agic happens when the teeth of two or more gears mesh together. This interlocking is the key to their function:

Transferring Motion: When one gear (the driver) rotates, its teeth push against the teeth of the mating gear (the driven). This direct physical contact forces the driven gear to rotate in the opposite direction (if mounted on parallel shafts) or a calculated direction (for bevel or worm gears). Motion is transferred directly from the input shaft to the output shaft.

Transmitting Torque: Gears don't just transfer spin; they transfer torque (rotational force). The force applied to the driver gear's teeth is transmitted directly to the driven gear's teeth. This allows small forces applied to one gear to generate larger forces at another – the principle behind mechanical advantage.

Changing Speed and Torque (Gear Ratio): This is perhaps their most crucial function. Gears of different sizes meshed together will rotate at different speeds. The gear ratio is defined as the ratio of the number of teeth on the driven gear (N_driven) to the number of teeth on the driver gear (N_driver), or equivalently, the ratio of their rotational speeds (RPM_driver / RPM_driven).

Speed Reduction & Torque Increase: If a small driver gear (fewer teeth) meshes with a large driven gear (more teeth), the driven gear will rotate slower than the driver gear. However, the torque on the driven gear's shaft will be increased. Think of a bicycle: pedaling a small front gear (driver) linked to a large rear gear (driven) makes it easier to climb a hill (high torque) but you pedal more times for each wheel revolution (low speed).

Speed Increase & Torque Reduction: Conversely, a large driver gear meshing with a small driven gear results in the driven gear spinning faster but with reduced torque. This is like shifting to a high gear on a bike for flat-out speed on level ground.

Why Teeth? And Why That Shape?

You might wonder why gears aren't just smooth wheels pressed together (like friction drives). Teeth are essential for:

Preventing Slippage: Teeth ensure positive engagement. There's no slippage, meaning motion and force are transmitted reliably and efficiently, even under high load.

Maintaining Constant Velocity Ratio: The specific curved profile of gear teeth (most commonly an involute curve) is mathematically designed so that even as teeth mesh and unmesh, they roll smoothly against each other. This ensures a constant velocity ratio between the two shafts – they don't speed up or slow down jerkily during engagement. This smoothness reduces vibration, noise, and wear.

Key Components & Terminology

Pitch Circle: An imaginary circle where the teeth effectively mesh. It's the reference for gear design.

Module (Metric) or Diametral Pitch (Imperial): Defines the size of the teeth – how coarse or fine they are.

Pressure Angle: The angle at which the force is transmitted from one tooth to another (commonly 20° or 14.5°). It affects tooth strength and smoothness of operation.

Addendum: The height of the tooth above the pitch circle.

Dedendum: The depth of the tooth below the pitch circle.

Backlash: The slight intentional gap between meshing teeth to prevent binding and allow for lubrication and thermal expansion.

Types of Gears for Different Jobs

Spur Gears: The simplest, most common type. Teeth are straight and parallel to the shaft axis. Efficient, but can be noisy. Used for parallel shafts.

Helical Gears: Teeth are cut at an angle (helix) to the shaft axis. Meshes more smoothly and quietly than spur gears, transmitting higher loads. Generates axial thrust. Used for parallel shafts.

Bevel Gears: Conical gears used to transmit motion between intersecting shafts, usually at 90 degrees. Teeth can be straight, spiral, or hypoid.

Worm Gears: Consist of a screw-like worm meshing with a worm wheel. Provides very high speed reduction ratios and can be self-locking (worm drives wheel, but wheel cannot drive worm). Used for non-intersecting, perpendicular shafts.

Rack and Pinion: Converts rotational motion (pinion gear) into linear motion (straight rack gear), or vice-versa. Used in steering systems, CNC machines.

Why Gears Matter

Gears are fundamental mechanical components because they offer:

Precise Control: Exact speed and torque ratios.

High Efficiency: Very little energy loss in transmission (often >95% for well-lubricated gears).

Compact Power Transmission: Transmit significant power through small spaces.

Reliability: Robust and long-lasting with proper maintenance.

Versatility: Available in countless sizes, types, and materials for diverse applications.

In Conclusion

Gears are elegant examples of mechanical engineering. By leveraging the simple principle of interlocking teeth on rotating wheels, they masterfully transform motion, multiply force, reduce speed, and change direction. Next time you shift gears in your car, wind a watch, or use any powered machine, take a moment to appreciate the complex choreography of those meshing teeth silently and efficiently making it all happen. They truly are the unsung heroes driving the mechanics of our world.

Comments